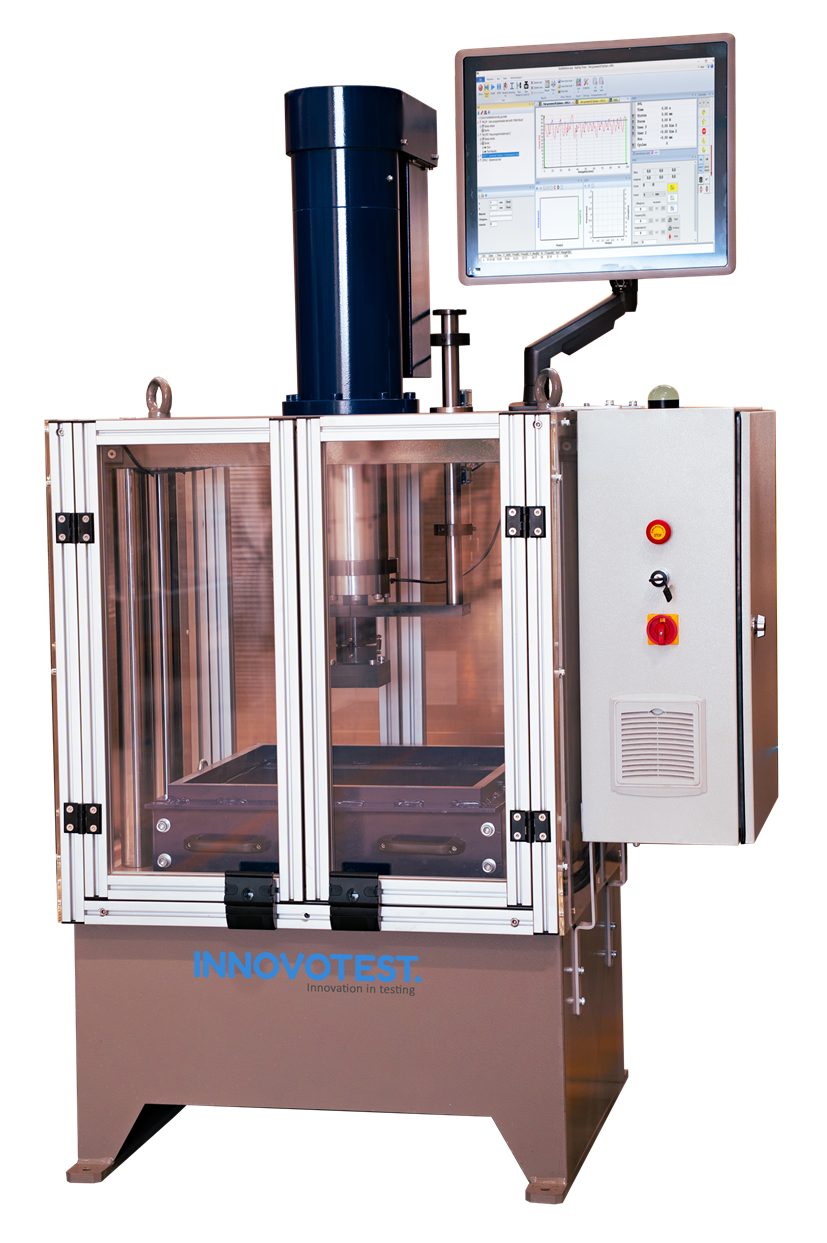

The F.CE Series are fully automatic servo electromechanical testing machines designed for a wide range of compression, flexural, energy absorption and similar tests on different specimens of various sizes.

Frame

4-column rigid construction with columns securely screwed to upper and lower crossheads, free of play.

Capacity: 10 - 300 kN

Actuation: Servo electromechanical actuator mounted on top.

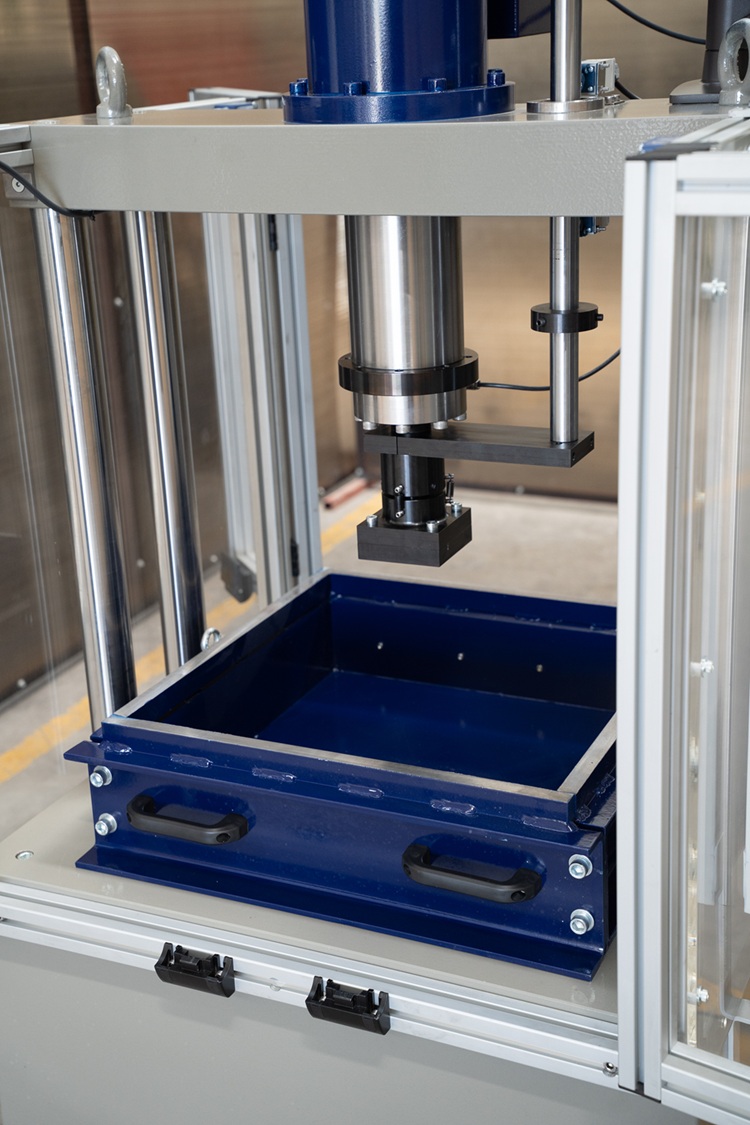

Sample loading: Easy front and rear access for efficient specimen handling.

The F.CE Series are fully automatic servo electromechanical testing machines designed for a wide range of compression, flexural, energy absorption and similar tests on different specimens of various sizes.

Frame

4-column rigid construction with columns securely screwed to upper and lower crossheads, free of play.

Capacity: 10 - 300 kN

Actuation: Servo electromechanical actuator mounted on top.

Sample loading: Easy front and rear access for efficient specimen handling.

Load Measurement

Measurement and control range: 1% to 100% of machine capacity.

Accuracy: Class 0.5 or better, in accordance with EN-ISO-7500-1.

High-precision load measurement ensures reliable and repeatable test results.

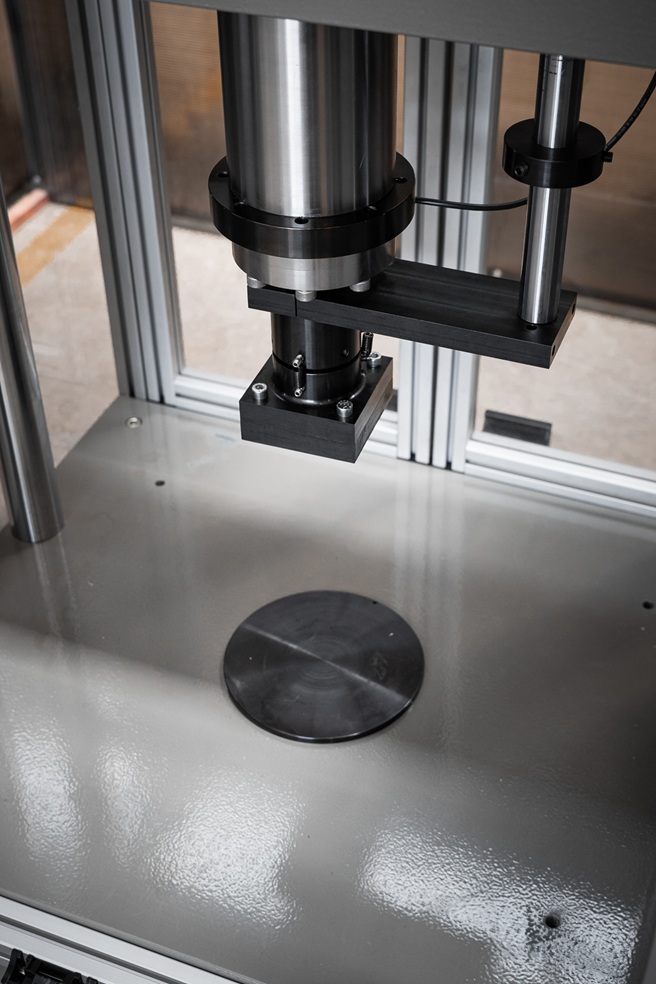

Displacement Measurement

Position sensor resolution: 0.001 mm.

User-selectable crosshead speed: 0.001 mm/min to 200 mm/min.

Measuring and Control Electronics

Equipped with Doli EDCi20 universal digital measurement and control electronics.

Installed in the control cabinet, operable via Remote Machine Control (RMCi) unit (optional).

Fully automatic test execution with programmable speeds for force, position, or strain-controlled tests.

Adjustable and sensitive break detection for early failure identification.

PC communication: Ethernet (RJ45) or USB 2.0.

Technical Data – Doli EDCi20

Expansion: 3 iSI modules (2 onboard)

Data acquisition and control speed: 2.5 kHz

Automatic sensor recognition via SGS intelligent sensor plug

Universal digital I/O: 8 inputs, 8 outputs (24 V DC)

Control output: Analog ±10 V or various digital interfaces

Incremental digital sensor connections (e.g., for position measurement)

iSYNC interface for multi-axis applications and connection of multiple EDCi units

Analog input amplifier (e.g., for load cell) with 20,000,000-step resolution

Emergency stop option on RMCi

Serial interface for external electronics (optional)

Universal Testing Software – Innovotest

Innovotest is an advanced and powerful testing software platform with intuitive workflows designed to:

Simplify operator training

Improve testing efficiency

Reduce safety risks

Key Features:

Configure unlimited live displays for force, displacement, time, and results.

Instant feedback on test status with real-time graphing of force vs. displacement or stress vs. strain.

Multi-graph viewing, zooming, and customizable control chart layouts.

Custom report templates for consistent, professional documentation.

Export reports in CSV or PDF with a single click.